Yitong titanium filter cartridge is based on pure titanium powder(Purity 99.7% or higher) as the main raw material. After high heating sintering, it appears uniform structure and high density pores. It also has great filtration precesion and high flow rate. It can be used for solid liquid, gas seperationand purification. The perfect strength and titanium media makes it is able to withstand harsh high temperature and pressure working environments.

A titanium powder sintered porous filter provides stable separation efficiency during the filtration process. The filter is made from titanium powder without the addition of any binders. Firstly, the titanium powder is compacted and shaped at room temperature using a liquid as the pressure medium. Subsequently, high-temperature vacuum sintering takes place. At temperatures below the melting point of the titanium powder, physical and chemical interactions, such as particle bonding, occur between the particles, resulting in a sintered material with the required strength and properties. Equipped with various connectors, the titanium powder sintered porous filter maintains a stable shape, excellent breathability, and superior separation efficiency.

The pore size, distribution, strength, and breathability of the titanium powder sintered porous filter are dependent on the powder fineness, compaction, and sintering process. The titanium powder sintered porous filter achieves micro-level fine filtration, effectively removing solid particle impurities from both liquids and gases.

The filter is made from 99.7% titanium powder and exhibits characteristics such as low density, high strength, excellent corrosion resistance, and good biocompatibility. It offers filtration precision ranging from 0.45 to 100μm.

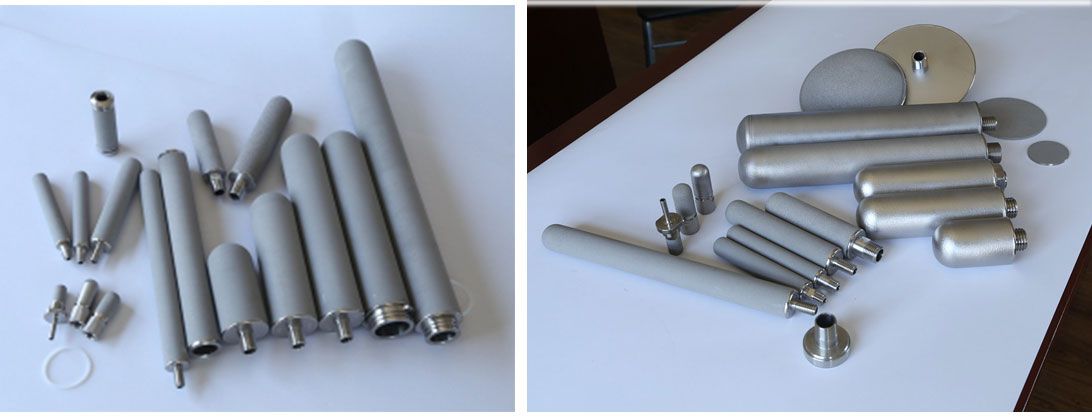

The titanium powder sintered filter can be used with various types of connectors and can be customized according to specific requirements. Here are some common connector types:

Standard connector: Including 215, 222, and 226 connectors, which are typically used in industrial filtration equipment and filter cartridges.

Thread connection: Such as M20, M30, M32, M42, and other types of threaded connectors, used to connect with other equipment or pipelines for more convenient filtration operations.

Flat/DOE: These connectors have a smooth surface and are suitable for certain specialized filtration applications.

Special Customized Connectors: Different types of connectors can be custom-designed based on users' specific needs and special applications to ensure the effective operation of the filter in specific environments.

The flexibility provided by these connector types makes the titanium powder sintered filter suitable for a wide range of industrial and laboratory filtration needs.

Cartridge structure | Filter media | Titanium powder |

Seal ring material | Silicone,Viton,EPDM,PTFE | |

Working situation | Max.working temperature | ≤200℃ |

Max. working pressure drop | 300Mpa/23℃ | |

Rating | 0.45, 0.5, 1, 2, 5, 10, 20, 50, 75, 100 micron | |

Length | 125, 250, 350, 500, 750, 1000 mm | |

OD | 20, 30, 50, 60, 70, 90mm | |

Connector | M20 M30 M32 222 226 | |

Note: All the above size are the normal size. Customized size is possible. Yitong Filter could help to design according to the application and requirement.

1. Microelectronics Industry:

Application Processes:

- Conveying ultrafine powder

- Grinding fluid filtration

- Flow control

- Flame retardant

- Pressure buffer

2. Food and Beverage Industry:

In food and beverage processing, food-grade porous metal filters can be used to remove impurities from products, ensuring the production of high-quality items. Porous metal distributors are utilized for gas aeration processes, such as carbonation and oxidation, in beverage production.

Application Processes:

- Clarification and filtration of beer and wine

- Prefiltration for mineral water

- Carbonation of soft drinks

- Purification and filtration of food and dairy products

3. Chemical Industry:

Porous metal materials find wide application in the chemical industry due to their ability to withstand complex and harsh conditions, making them the preferred choice for filtration, separation, and catalysis processes.

Application Processes:

- Filtration and separation of crystals and catalysts

- Removal of sand in petroleum extraction

- Separation of oil and wax in petroleum refining

- High-temperature liquid and gas filtration

- Filtration of corrosive liquids and gases

- Expansion within reactors

- Waste gas and exhaust treatment

4. Water Treatment Industry:

Porous metal materials often possess characteristics like corrosion resistance, oxidation resistance, high-temperature resistance, high strength, and cleanability. Consequently, they have longer lifespans compared to polymer and rubber products in the water treatment industry.

Application Processes:

- Prefiltration for seawater desalination

- Industrial and municipal wastewater treatment

- pH adjustment aeration

- Ozone aeration, disinfection, and oxidation

5. Biomedical Industry:

Filtration, separation, and aeration processes are widely and crucially employed in the biomedical field. Titanium powder sintered filters are used in various stages, such as filtration, separation, purification, and aeration, to meet the strict requirements of the biomedical industry.

Application Processes:

- Filtration of catalysts and impurities in pharmaceutical products

- Aeration during fermentation processes

- Cross-flow filtration

- Gas agitation

- High-temperature filtration

The sintered metal filter is highly durable and possesses excellent filtration efficiency, making it suitable for a wide range of applications such as air and liquid filtration, chemical processing, and medical equipment. We offer sintered metal filter products in various shapes, sizes, and materials to meet specific customer requirements. High-purity filters and distributors are specifically designed to meet strict requirements for particle removal in process gases, such as in semiconductor applications.

Sintered metal is a filtration material manufactured by compacting metal powder at high temperature and pressure, resulting in a solid porous material. This process allows for the production of complex shapes and high-precision parts. Using sintered metal media for gas, solid, and liquid separation in filtration systems has proven to be an effective alternative to other separation techniques that may face risks of pressure spikes, heat, and harsh environments. Compared to leaf filters, filter bags, and plate-frame filters, sintered metal is highly effective in particle elimination, has good efficiency, is easy to clean, and has a long service life.

Common materials include bronze, stainless steel, and various alloys. Bronze is the most popular and cost-effective alloy metal used for sintered filters. You may opt for other metal types or alloys for reasons like higher strength, better corrosion resistance, or higher-temperature applications. Stainless steel is another popular material, known for its excellent heat resistance and corrosion resistance, with 316L stainless steel being particularly effective.

For more extreme environments, nickel alloys might be necessary. Options include Monel alloys, Hastelloy alloys, and Inconel alloys. However, these alloys tend to have higher costs due to the difficulty in processing and their base components being more expensive metals.

Yitong is a professional supplier of porous metal filters, capable of producing sintered porous metal filters in various materials and sizes. Customization is also available to meet specific customer requirements. Feel free to contact us if you need any of our products.

Our products: metal powder sintered filter element, sintered mesh filter element, pleated metal filter element.

Raw material: stainless steel 304/316L/904L, Hastelloy, powder, titanium powder, etc.

Our workshop

Whole production processing from raw materials to finished product in our own factory OEM&ODM is available

Quality control

Raw material composition analysis Analysis of filter media pore size distribution, flow capacity, etc. Testing service of dirty holding capacity, flow capacity and bubble point