Yitong SS Sintered Filters are designed to provide high quality particulate Removal in Process Steam together with high flow rate and dirt holding capacity, thereby allowing long system lifetime and cost effective operation.

Yitong SS Sintered Filters are designed to provide high quality particulate Removal in Process Steam together with high flow rate and dirt holding capacity, thereby allowing long system lifetime and cost effective operation.SS Sintered filters are made from fine SS powder is sintered to form filters in cylindrical shape. SS Sintered elements can be cleaned by immersion in dilute hydrochloric acid, ultrasonic bath, clean water or air depending on the type of contamination, which gives it a long service life.

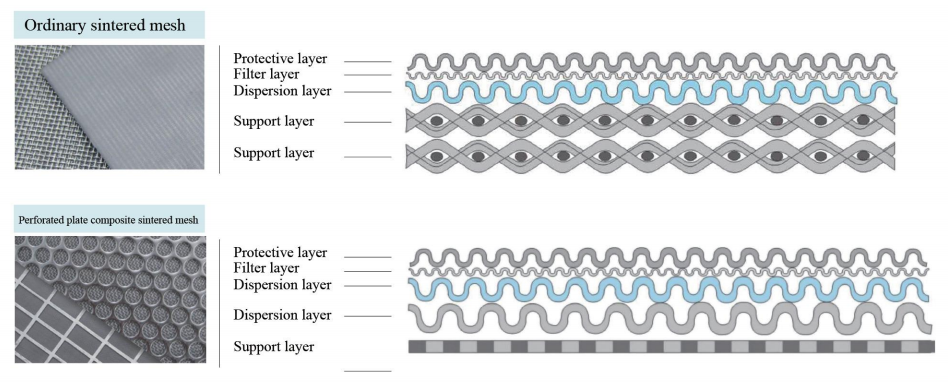

Standard five-layer sintering mesh is one of the most widely used sintering mesh, it is a new type of filter material made of five layers of stainless steel wire mesh stacked together in order and sintered. It is composed of four parts: protective layer, filter layer (working layer), dispersion layer and support layer. The filter material has the characteristics of stable filtration accuracy, good strength, easy to back cleaning, and long service cycle. High strength, good rigidity, high mechanical strength and compressive strength, good processing, welding and assembly performance, easy to use. The accuracy is uniform and stable, and the filtering performance can be uniform and consistent for all filtering accuracy, and the mesh does not change in use. Strong corrosion resistance, strong heat resistance, can be used for -200℃ to 600℃ temperature environment and acid and alkali environment filtration. Simple cleaning, countercurrent cleaning effect is good, can be used repeatedly, long life.

1 316L Stainless Steel Filter Cartridge

2 Exceptionally high Flow Rate

3 High Dirt Holding Capacity

4 All Welded Construction, NO Leachable

5 No Migration, Non Fiber Releasing

1 Steam filtration

2 Filtration of the high viscous, strong corrosive and strong polarized liquids

3 Filtration of liquids under condition of high temperature and pressure

4 Decarburization filtration

Cartridge structure | Filter media | 304, 316L Stainless steel |

Seal ring material | Silicone rubber, EPDM,PTFE | |

Working situation | Max.working temperature | ≤200℃ |

Max. working pressure drop | 300Mpa/23℃ | |

Rating | 1, 2, 5, 10, 20, 50, 75, 100 micron | |

Length | 210, 250, 350, 500, 750, 1000mm | |

OD | 47, 65, 76, 86, 100mm | |

Connector | M20 M65 222 226 | |